Production models

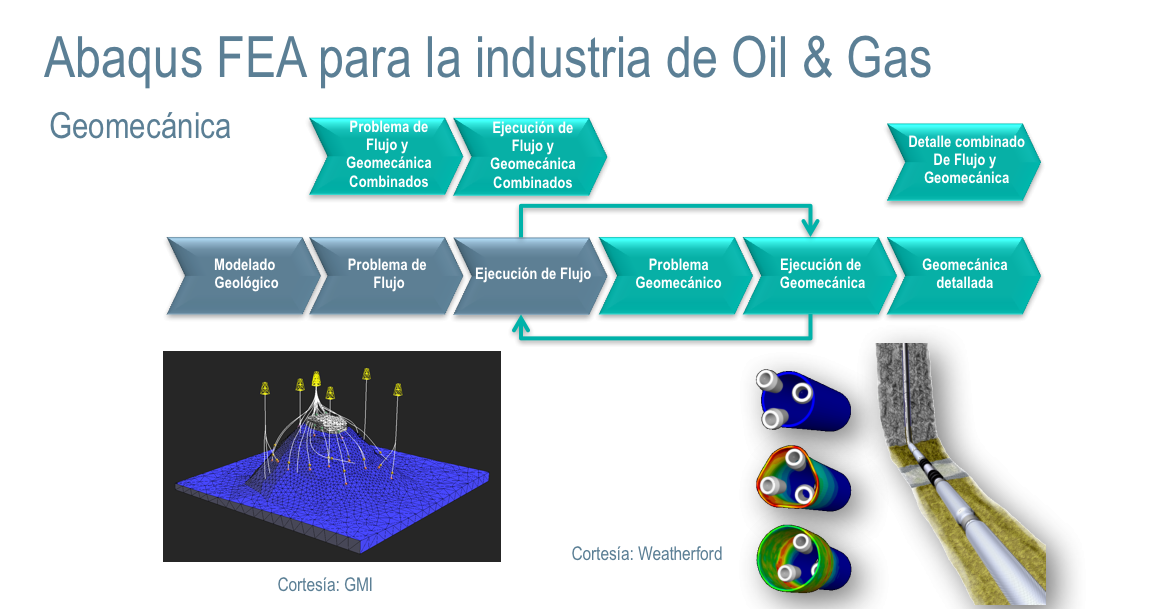

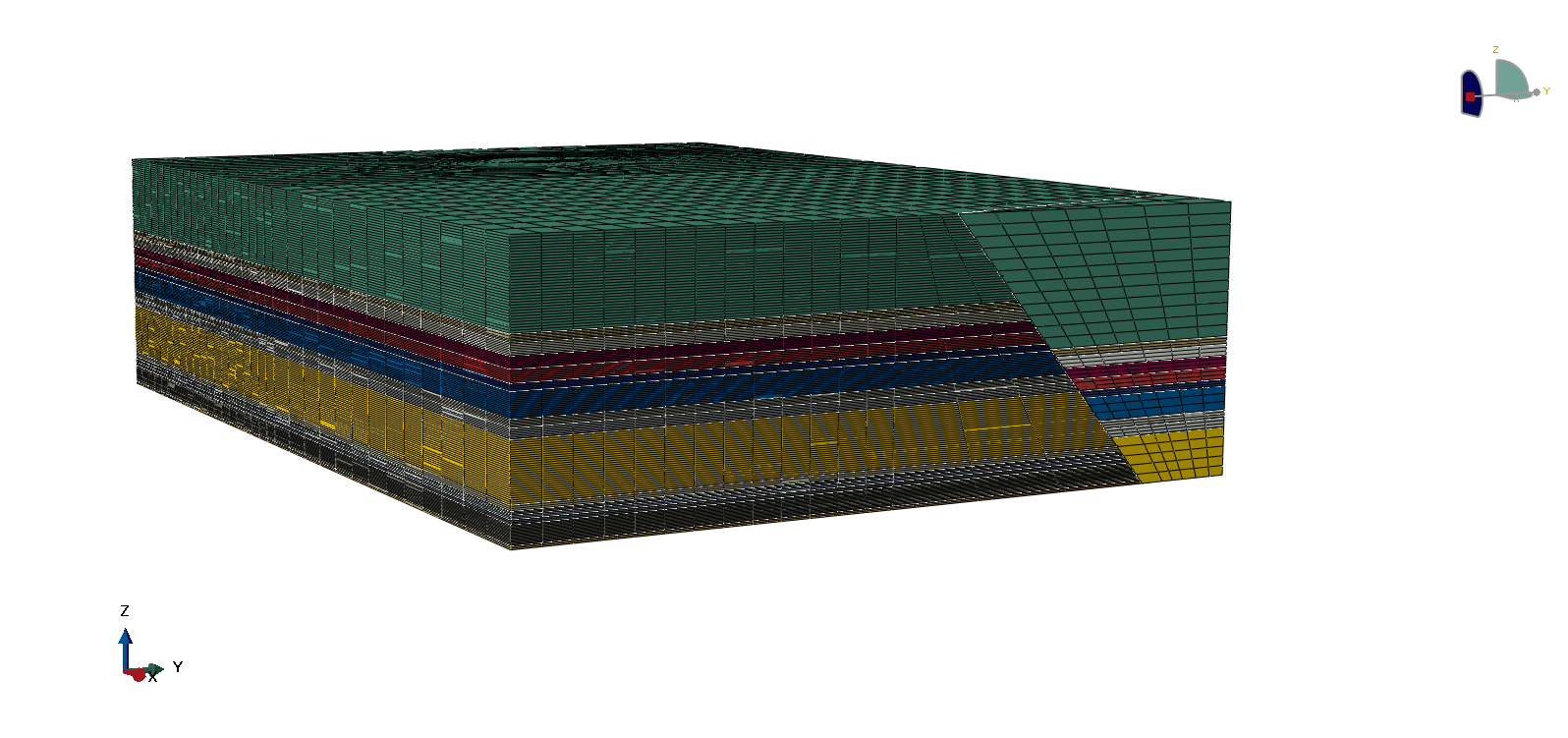

While conventional reservoirs are governed by buoyancy forces, non-conventional reservoirs (mudrocks) are governed by pressure forces. Hydraulic fracture processes and production processes generate modifications in stress and pressure fields which affect both relative permeabilities as well as wells integrity, therefore modifying their future development possibilities.

Ver mas The prediction of medium and long term production of reservoirs developed by means of triphasic flow simulations (industry standards are based on finite differences) have systematically failed because they are based on a geologic static model. These analyses do not take into account subsidence permeability changes produced by depletion or by local modifications of stress of the fracture process. Available technology allows the coupling of the geomechanical model with the standard flow models so as to generate a geologic dynamic model which enables to update permeabilities during the production process, as well as to evaluate failure reactivation phenomena and surface subsidence.

Ver Menos

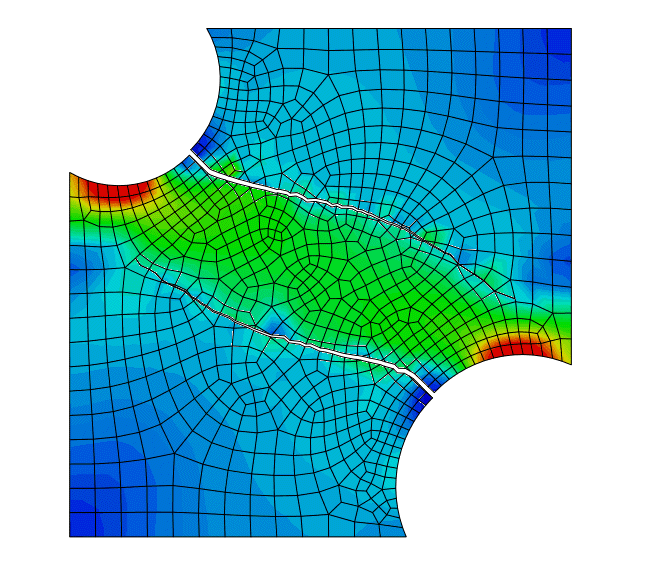

Simulation of hydraulic fracture propagation

The extension of the hydraulic fracture and its interaction with proximate wells and pre-existing fracture systems can be modelled in such a way that wanted and unwanted effects are estimated numerically, selecting the most suitable tested options of development.

Ver mas The geomechanical model is enriched with fracture parameters obtained under laboratory conditions, in such a way that the fracture propagation in a 3D simulation of a porous elastic medium has a correlation with the field data. The different fracture alternatives, with its stages and sequences, are tested in order to analyze the most viable in terms of efficiency and collateral effects such as casing constraint in adjacent wells. Stress shadow phenomena are revealed as a result of the obtained models. The final state of these simulations are the foundation for production models.

Ver Menos

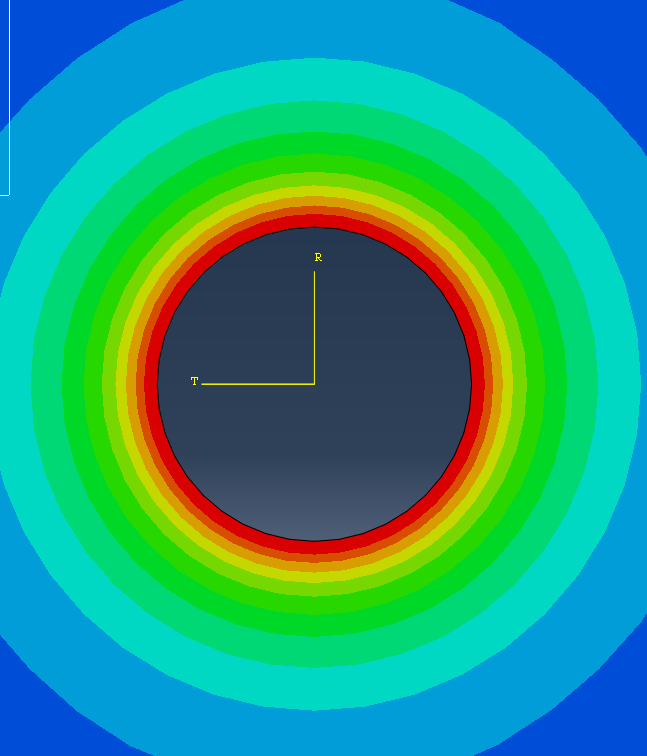

Well stability and completion

The numerical simulation models of well stability and 3D completion (fabric anisotropy and stress field) allow a test of the different mud densification policies, as well as different well geometries, casing centralization and concrete shields.

Ver mas The problem with well stability imply both the phenomena associated to low mud density (casing collapse) and high mud density (flow loss because of seepage or unwanted fractures in the formation). Mechanical description permits to establish a predictive model which aids the drilling engineer to plan the well, while the chemical description assists the selection of non-reactive mud with the formation to be drill. Along the life of a well, the concrete shield is subject to different reservoir conditions. The changes in pressure and temperature owing to production, hydraulic stimulation and tectonic activity may damage it, ranging from small chronic leakage, which cause a loss of casing sustained pressure (SCP) to the total loss of the well. Therefore, predicting the behavior of the casing of a production formation and guaranteeing the well integrity is vital to reduce operation costs and optimize hydrocarbons recovery. The models developed enable the evaluation of failure caused by the annular debonding of cement-casing, the annular debonding of cement-formation, failure of the cement under compression and failure of the cement under tension, both due to hoop tension as well as longitudinal tension.

Ver Menos